| Paver Products- Paver Intro. | Wirecut | Cobble | Sandblast | Laying Patterns | Paver Acc. | Installation Guide - | ||||

|

||||

Installation of Clay Flexible Pavement Flexible pavement is typically the most economical paving system because it is simple to install and involves less labor and fewer materials. Applications for flexible pavement cover a wide area, ranging from residential patios to city streets. The thickness of each layer in a flexible pavement depends upon the imposed loads and the properties of each layer. A pavement subject to heavy vehicular traffic requires a thicker base than a pavement subject to pedestrian traffic.

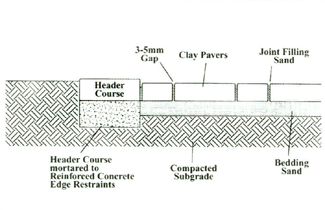

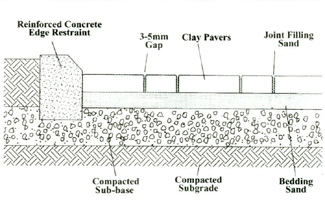

Pathway Figure 1 is a typical example of pathway for pedestrian application. The clay pavers are laid directly on the compacted sand and sub-grade. This application works best when the sub-grade is compacted. A geo-textile can be used beneath the sand base where the soil conditions are poor. Driveway Figure 2 shows the laying structure of pavement for driveway. Many commercial pedestrian and vehicular applications can use this type of assembly. Pavements subjected to vehicular traffic must be designed to accommodate the wheel loads. Class of Pavement Specification required for different classes of pavers based on AS 1226.1-1984

Preparation Works Sub-grade The sub-grade should be properly compacted and prepared to the required profile to facilitate drainage systems such as piped or subsoil drainage. The load-bearing capacity of the sub-grade determines the depth of additional base material required. The shear strength of sub-grade is indicated by the California Bearing Ratio (CBR) which is widely used as a mean to assess the strength of sub-grade for road design. (please refer to BS6677: Part 2) Sub-base The sub-base layer is the main load-bearing layer of a pavement. Its function is to evenly spread the load of any traffic on the pavement to the sub-grade beneath. A well constructed sub-base will prevent settlement and chanelization due to rutting of paving units caused by vehicles traveling repeatedly over the same line. The sub-base should be compacted granular road base materials with sufficient voids to allow water running through to the drainage system in the sub-grade. The required thickness of base course depends on the SBR of sub-grade. For a light vehicular traffic driveway on a sub-grade of SBR 5%, the base course requires a thickness of 220 mm. The corresponding recommended sub-base thickness can then be estimated from table below (extracted from BS6677: Part2),

Bedding Course The bedding course is preferably a layer of well-graded washed sand containing not more than 3% clay or silts by weight and with grain sizes complying with the requirements of Grade C contained in table 5 of BS882:1983. The sand is normally compacted to a uniform thickness of 30 to 50 mm. Crossfall and Gradient Adequate drainage of the pavement surface is essential to prevent ponding of water and possible seepage into bedding and sub-base. Prolonged accumulation of subsurface water will reduce the load capacity of the sub-grade due to weakening of the soil and cause deformations of the pavement. The best way to improve drainage is to provide sufficient crossfall and gradient of the pavement to facilitate drainage of running water on the surface and within the base and bedding courses. To minimize the possibility of accumulation of surface water, crossfalls should ideally be maintained at 1:40, and longitudinal gradients at about 1:100. Detailed guidance is given in BS6367 Drainage of Sub-grade and Base Maintenance of proper drainage of the sub-grade is vital for the load-bearing capacity and stability of pavement. Drainage systems should be installed in the sub-grade and the profile of the sub-grade should be adjusted as necessary to provide adequate drainage. All piped and subsoil drainage construction located beneath the pavement should be completed in conjunction with sub-grade preparation before the commencement of base course construction. It is important to note that failure to provide proper drainage of a pavement can cause all sorts of problems:-

Laying of Flexible Clay Paver Laying should be commenced from a starting edge on the prepared bedding course in the desired laying pattern. The first few rows of pavers should be laid carefully. Initial care will ensure that the laying that proceeds true to line and pattern. Alignment should be checked from time to time during the laying process, so that simple adjustments can be made to assure a clean, consistent bond pattern throughout the process. To ensure a harmonized appearance, it is always a good practice to select pavers from three or more packs randomly. A Code of Practice for design of flexible clay paver is given in BS 6677: Part 2 for design of light traffic pavements, and BS 6677: Part 5: 1986 for Method for Construction of Pavements. Joints Care should be taken during laying to ensure that a space of 3 to 5 mm is left and no point contact exists between adjacent pavers in order to reduce the risk of edge chipping. The space should be filled with dry, clean fine sand to form finished joints thus providing interlocking effect. Complete joint filling with correct type of sand is essential for effective interlock and shear transfer. The sand should comply with grading F as defined in BS882: 1983. Dry evenly fine graded sand can be spread over the pavement and brushed into the joints before compaction begins. After laying onto the prepared sand bed and joints filling with sand, pavers should then be compacted into position by two or three passes of vibrating plate compactor fitted with a neoprene pad (picture on the right). As recommended in BS 6677: Part 3, the plate area should be at least 0.20 m2. it should transmit an effective force of 50-75 kN/m2 at a vibration frequency of between 60 and 100 Hz. Compaction should not be performed closer than one meter from any unrestrained edge. Further sand should then be applied and the procedure repeated.

Edge Restraints for Paved Areas A rigid edge restraint along the perimeter of the paved area is necessary to prevent lateral movement of the paving units leading to subsequent lost of interlock and to retain the bedding course sand. Concrete, stone, metal, some types of plastic or a soldier course of mortared brick set in concrete can serve as an edge restraint. The border can be planned not only to complement the design of the pavement, but also to provide a channel for surface runoff. Pavement accessories can be used to create elegant curbing for your paving project while also act as an edge restraint. Edge restraints should be formed before compacting adjacent units and the restraints, together with any concrete haunching, should be mature before vibration of the surface course is undertaken. Haunching to an edge restraint should be continued down to the level of the underside of the bedding course. Where appropriate, drainage should be provided at edge restraints to prevent building up of a head of water in the bedding course |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compaction

Compaction